RISK & SAFETY ANALYSIS

1 System:

Tekfen Engineering organizes its safety related activities by a risk-based process safety managementsystem (RBPSMS). In addition to establishing a risk based design philosophy, this system ensures righttiming, right detail and right person for the safety engineering activities. RBPSMS is builton 4 pillars and 20 elements.

The aim of the TEKFEN’s 4 pillar-20 element system may be summarized as:

· Define the methodology for safe design that is preparedness to hazardous conditions and freedom from the acceptable level of risk

· Harmonize the safety in design philosophy with operational safety management philosophy with a tailored industrial best practice algorithm

· Identify and define the safety engineering activities and deliverables matched to process design lifecycle

· Identify the secondary issues related to design safety and propose a systematics to handle them

· Define the interaction mechanisms (information, outputs, authorization etc.) of safety engineering activities with other disciplines

· Present a methodology to executives for the management of safety

· Present the systematics of how design engineering activities are reviewed and authorized in terms of safety at TEKFEN Engineering

Designs.

2 Design Safety Lifecycle Management:

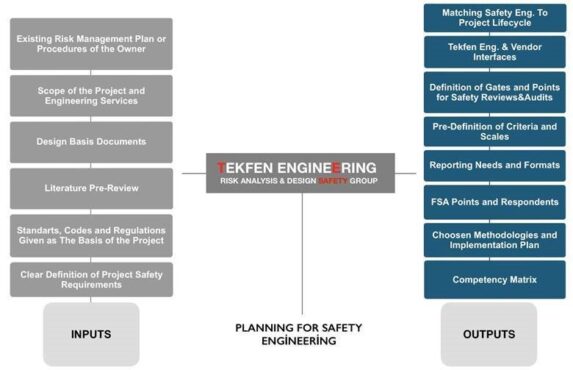

Hazard Identification and Risk Analysis (HIRA) is a collective term that encompasses all activities involved in identifying hazards and evaluating risk at facilities, throughout their life cycle, to make certain that risks to employees, the public, and/or the environment are consistently controlled within the organization’s risk tolerance. To maintain a dependable risk identification and analysis practice through a project it is necessary to have a structured planning algorithm as given below:

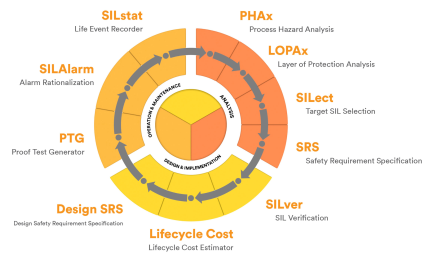

Tekfen Engineering uses EXSILENTIA (from EXIDA) for seamlessintegration of whole safety engineering activities such as PHA, targetSIL selection, SIL verification, SRS writing, proof test generation, costanalysis and alarm management. This algorithm is also in completecompliance in terms of IEC 61511.

The PHAx and LOPAx modules of the EXSILENTIA enables the Tekfen Engineers record the identified Alarms during process hazard analysisand later on during the detailed design engineering phase, all of therecorded alarms are called back by using the SILAlarm module with allthe information necessary for an alarm rationalization study.

3 Services:

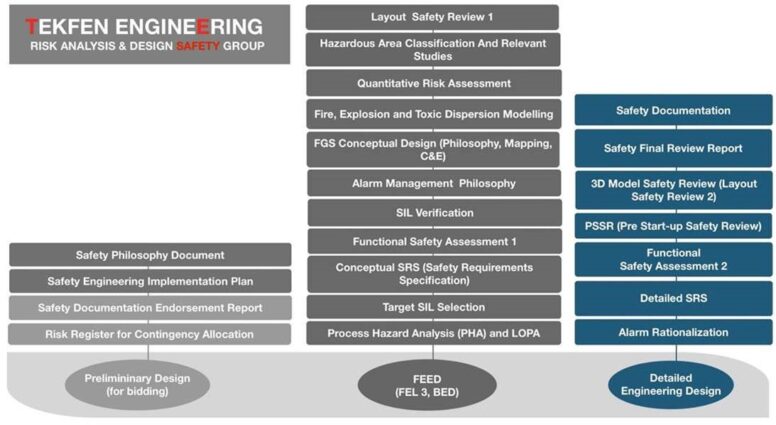

Typical deliverables of TEKFEN Engineering Risk Analysis and Design Safety Group are addressed to project lifecycle and can be seen at below:

4 Third Party Services:

Tekfen Engineering Risk Analysis and Design Safety Group has the competency and reference to execute any of the design safety activities hovewer, typical third party services given so far may be summarised as below:

· HAZOP-HAZID (EXSILENTIA SILver)

· LOPA

· SIL VERIFICATION (EXSILENTIA SILver)

· FLARE AND/OR COLD VENT SIMULATION PHAST (+3D MODULE)

· RELIEF SYSTEM SAFETY REVIEW

· ALARM RATIONALIZATION (EXSILENTIA SILAlarm)