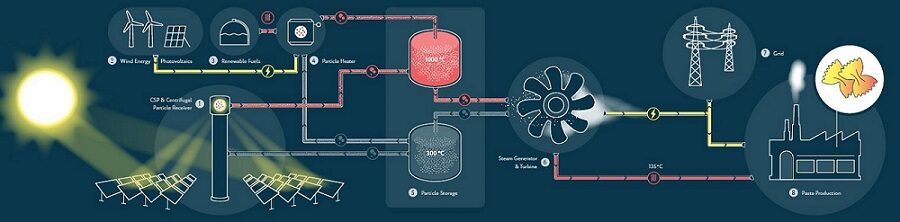

HIFLEX

Hi-Flex is a tower type concentrated solar power plant which will be built in Barilla’s Foggia pasta factory in Italy to supply process steam. During the HIFLEX project the worldwide first complete pre-commercial system using particle technology will be developed, built and demonstrated by eleven different partners; from seven different countries. The demonstration plant with 20 MWh thermal energy storage and a 2.5 MWth receiver includes all components of a commercial-scale plant except for the state-of-the-art steam turbine.

The HIFLEX concept is based on the innovative solid particle technology. Cheap ceramic solid particles (bauxite or similar) are used as heat transfer and storage material. The wide applicable temperature range of such particles (up to 1000°C, no freezing) enables the techno-economic optimization of lower and upper particle temperatures in the process. A study on the optimal temperature range has shown that a large temperature spread leads to a significant cost reduction.

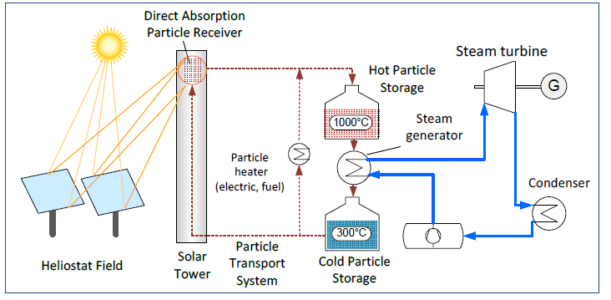

Simplified scheme of solid particle CSP system combined with a Steam Rankine Cycle

A simplified scheme of the HIFLEX system with solid particles is shown in above Figure. The solar radiation is concentrated by heliostats onto the direct absorption particle receiver, where the particles are heated up (e.g. to 1000°C) while passing through the receiver. The hot particles are then stored in the hot storage container. For power production, particles are passing through the steam generator to generate steam for the steam cycle for power production. After passing through the steam generator, the cooled particles are collected in the “cold” storage (e.g. at 300°C). During sunshine hours, the particles are transported up to the tower and get heated again. Hot and cold temperatures of the particles can be selected according to a techno-economic optimization, without strict technical limits. Unlike with molten salt, the particle system does not experience the danger of fluid freezing and thus does not need any trace heating.

The system consists of:

- Thermal storage with 20 MWth to provide 800 kWth for 24h, using solid particle technology for higher storage density and lower cost

- Solar particle receiver, peak thermal power: 2.5 MWth, designed for 1000°C

- Heliostat field with about 6000 m² reflector area

- Particle-driven steam generator for the demonstration of high quality steam generation at 620°C (800 kWth for 24 h operation)

- 100 kW electric and 800 kW renewable-fuel particle heaters

- Heat exchanger and connection for continuous 135°C process heat supply to Barilla pasta plant.

Project contains 9 work Packages; All partners’ responsibilities are in below;

- Kinetic Technology-Nextchem (Italy): coordinates and supervises the project.

- DLR (Germany): designs the centrifugal particle receiver, electrical heater and back-up heater system with HelioHeat. Works on designing the steam generator that is supported by particle-CFD simulations and is foces on material issues such as particle characterization and optimization of the particle composition.

- Barilla (Italy): is the end user.

- John Cockerill (Belgium): is responsible of the particle Steam Gnerator basic and detail engineering.

- Sugimat (Spain): is in charge for the manufacturing of steam generator and the condenser.

- Tekfen (Türkiye): is mainly responsible for the optimization, detailed engineering and manufacturing of heliostats and heliostat field.

- HelioHeat (Germany): manufactures and delivers the centrifugal Particle Receiver, the electric and the backup particle heater.

- Indygo Tech Mineral (Poland): is responsible for the production and delivery of the ceramic particles.

- Dürmeier (Germany): is reponsible for design and delivery of the transport system for particles.

- Quantis (Switzerland): assessed the environmental and integrated sustainability performance of HiFlex project.